- Home Page

- Company Profile

-

Our Products

- Resistance Heating Alloy

- 1.4767 Fecral 235 0Cr23Al5 Strip

- NiCr8020 Resistance Alloy Nichrome Flat Strip

- Nichrome Resistance Alloy Strip Ni80 Flat Wire

- Copper and Manganin Welding Strip

- 12SWG 14SWG 16 SWG 0Cr21Al4 0Cr23Al5 0Cr21Al6 FeCrAl 23-5 FECRAL Alloy Resistance Wire for Electric Oven

- CuMn12Ni Copper Manganin 43 47 29 Shunt Alloy Resistance Strip

- Electric Resistance Heating Strip

- FeCrAl 145 Resistance Strip

- FeCrAl 145-0cr25al5 Electric Heating Alloy Round Bar

- FeCrAl Alloy Resisohm 135 Plate for Brake Resistor

- Higher Surface Loading Capability Heating Wire

- High-resistance Heating Wire 0.2mm 0Cr21Al6Nb for Heating Element

- FeCrAl Wire Resistance Heating Wire

- High-resistance Heating Wire 0.16mm 0Cr21Al6Nb for Heating Element

- Hti 301 Strip Cold Coil

- Ni35Cr20 Ni30Cr20 NiCr 35-20 NICR D 40-20 Ni40Cr20 Nichrome High Resistance Alloy Wire

- Nichrome Alloy NiCr80-20 Wire

- Ni80Cr20 X80H20 Nichrome NICR Alloy Resistance Wire

- Nickel Chrome Electrical Resistance Ribbon

- 19x0.574mm Nichrome Ni80Cr20 Nichrome Stranded Wire

- Nickel Chromium Alloy Electric Resistance Nichrome 60 Resitor Strip

- NiCr 80-20 0.5mm Ni 80 NICR 90-10 Nichrome Electric Resistance Wire for Hair Dryer

- Resistance Heating Flat Ribbon

- Resistance Strip Alloy 675 Ni60Cr15 Nickel Chromium for Plate Resistors

- Thermocouple Cable

- B Type Thermocouple Wire

- Brown Color Class 1 Accuracy K-type Thermocouple Extension Wire Without Shielding

- Chromel Alumel Bare Wire for K Type Temperature Sensor

- Insulated K Type Thermocouple Cable

- Customized Color Coding Glassfiber Cable

- Thermocouple Wire Bare Wire

- Customized Thermocouple Extension Cable

- Flame Retardant PVC Insulated J Type Thermocouple Extension Wire

- High Temperature Fiberglass Coating 20AWG 24AWG 22SWG K Type Thermocouple Cable

- K Type Corrosion-resistant Thermocouple Extension Cable

- K Type Thermocouple Cable with PFA

- K-type Thermocouple Extension Wire

- R Type Thermocouple Wire

- S Type Thermocouple Wire

- Thermocouple Extension Cable Type K Chromel Alumel Cable

- Thermocouple Extension Cable with Anti-interference Shielding

- Thermocouple Wire K Type Chromel Alumel Extension Cable

- Class 1 Accuracy K-type Thermocouple Extension Wire

- T Type Thermocouple Wire

- K Type Fiberglass Insulated Thermocouple Cable for Thermocouple Sensor

- Special Accuracy Thermocouple Extension Cable with Fiberglass

- Resistance Alloy

- 3x0.26mm Copper Nickel Cuni44 Flat Wire

- Alloy90 Copper Nickle Wire for Motor Control

- Alloy320 Copper Nickle Wire for Temperature Sensitive Resistors

- Copper Nickel Alloy Heating Wire

- Copper Nickel Wire

- Copper Nickle Wire CuNi10 for Temperature Sensitive Resistors

- Copper Nickle Wire for Motor Control

- Copper Nickle Wire for Precision

- CuMn12Ni Copper Manganin 43 47 29 Shunt Strip Tape

- Cu-Ni 102 Copper Nickle Wire for Heating Wires

- CuNi102 Alloy 294 Copper Nickle Wire for Precision and Vitreous Resistors

- Cupron Copper Nickle Wire for Precision

- Low Resistance Alloy 45 1.0-1.9mm Copper Nickle Wire for Precision

- Low Resistance Alloy 45 Copper Nickle Wire

- Low Resistance Alloy 294 1.0-1.9mm Copper Nickle Wire for Precision

- Low Resistance Cu-Ni 44 Copper Nickle Wire

- Low Resistance MWS-294 Copper Nickle Wire

- Low Resistivity Cuprothal 15 Copper Nickle Wire

- MWS-294 Copper Nickle Wire for Precision

- MWS-294 Copper Nickle Wire for Temperature Sensitive Resistors

- Resistance Alloy90 Copper Nickle Wire

- Resistance CuNi10 90-10 Copper Nickel Alloy NC015 Electric Heating Wire

- Nickel Alloy

- 0.01mm Ultra Thin Pure Nickel Foil

- Alloys Wire Metal-sheathed Tubular Elements

- 0.005X650mm Alloy Foil

- 0.025mmX300mm High Precision Ultra-thin and Ultra Wide Nickel Foil

- Chromium Aluminum FeCrAl 23-5 Alloy 815 0Cr23Al5 Strip

- Ni200 Ni201 N4 N6 Pure Nickel Foil

- Corrosion-resistant High Electrical Resistance Nickel Chromium 80-20 Bar

- FeCrAl 750 720 715 875 Iron Chromium Aluminum Electric Heat Resistance Alloy Resistor Strip

- FeCrAl Alloy Strip 0cr21al6nb 0Cr23Al5 Strip

- Flat Ni80Cr20 Ni-Cr Wire Nichrome Ribbon NICR Alloy Resistance Wire

- Heating Electric Resistance Alloy Tape

- High-temperature Resistant Ultra-thin Nickel Foil Used for Connector Contacts

- High-temperature Resistant Ultra-thin Nickel Foil

- Nichrome Alloys Wire DIN 2.4817 for Electric Blankets

- Nichrome Alloys Wire Inconel 600 for Heating Equipment

- Nickel 201 Strip Foam

- Nickel Wire for Wire Mesh Application

- Resistance Nickel Chrome Stranded Wire

- Ultra Thin and Wide Nickel Foil with High Corrosion Resistance

- Ultra Thin Nickel Foil 0.035mmX350mm with Strong Antioxidant Properties

- UNS N06600 Nichrome Alloys Wire for Heating Cables and Rope Heaters

- Pure Nickel 996 Ultra Thin Foil

- Ultra Thin Pure Nickel Foil

- Resistance Alloy Nicr8020 Sheet

- Copper Alloy

- 0.134mm Manganin Wire with Resistance

- Alloy 0.03-8.0mm Manganin Wire

- Beryllium Copper Strip CuBe2 Strip

- 0.13mm CuNi2 Copper-Nickel Alloy Wire for Under Floor Heating Cable

- C1100 Copper Strip

- C11000 Pure Copper Strip

- C11000 Pure Copper Tape

- CuNi30 Copper Nickel Alloy Wire

- CuNi30Mn Copper Nickel Resistance Heating Elements Alloy Wire

- CuNiMn3-12 Manganin Wire with Resistivity

- Nickel Silicon Alloy Tape

- CuNiMn3-12 Wire

- High Temperature Resistant Enameled Manganese Copper Wire

- Enameled Manganin Wire

- Half Hard Pure Bare Copper Foil

- High Quality Alloy 290 Manganin Wire with Resistivity

- Low Resistance Nickel Copper Alloy Wire

- Manganin Wire

- 360HV Beryllium Copper Strip

- Bright Constantan Strip

- CuMn7Sn Copper Manganese Alloy Resistance Wire for Shunt Cumn Copper Manganese Wire

- Low Temperature Heating Copper Nickel Wire

- Precision Alloy

- 0.5mm Soft Magnetic Alloy Wire

- 1J79 Permalloy Wire 7904 Soft Magnetic Alloy Wire

- 140B Thermal Bimetallic Sheet

- Electric Heating Resistance Bare Heating Element Pipe Heating Cable Kan-thal A1 Fecral Alloy Wire

- FeNi50 Soft Magnetic Alloy Strip

- Hy-Ra49 Soft Magnetic Alloy Sheet

- Low Thermal Performance Bimetal Strip

- FeAl12 FeAl Soft Magnetic Alloy Strip

- Magnetic Shield Tape

- Mu 49 Soft Magnetic Alloy Wire

- Nickel Alloy Steel Round Bar

- Nickel-base Alloy Supermalloy FeNi50 Mu 49 Round Rod

- P675R Thermostatic Bimetallic Strip for Temperature Controller

- Precision Alloy 1j22 Wire

- Soft Magnetic Alloy Mu 49 FeNi50 Round Bar

- Thermal Bimetal Sheet for Temperature Controller

- Thermal Bimetal Sheet

- Thermal Bimetallic Strip

- Thermobimetal Strip

- Thermostatic Bimetal Sheet for Temperature Controller

- Thermostatic Bimetal Strip for Thermometer

- Permalloy Wire Ni79Mo4 Precision Alloy Soft Magnetic Alloy

- Pure Nickel

- Welding Wire

- Thermal Spray Wire

- 1.6mm ERNiCrMo-3 Weld Inconel Alloy Wire Inconel 625 Mig Welding Wire

- 95-5 Ni95al5 Thermal Spray Wire

- Alloy 82 Nickel-Chromium Welding Wire

- CuMn7Sn Copper Manganese Alloy Strip

- ER70S-3 Welding Wire

- ER70S-6 Mild Steel Welding Wire

- ER310-ER310S High-Temp Welding Wire

- ERNiCrMo-3 Mig Welding Wire

- Inconel 625 Mig Welding Wire Nickel Alloy Wire

- Inconel 625 Nickel Alloy Wire

- Inconel 625 Thermal Spray Wire

- Ni200 Ni201 Nickel Alloy Welding Wire

- Ni200 Ni201 Pure Nickel Welding Wire

- Nickel-Chromium-Molybdenum ERNiCrMo-3 Inconel 625 Alloy Wire

- Pure Nickel Welding Wire

- Super Pure Magnesium Wilding Wire

- TA-FA 60T Flame Spray Wire

- TIG-MIG Welding Wire

- UNS N03301 Thermal Spray Wire Alloy Wire

- 1.6mm Mig-Tig Mild Alloy Welding Wire

- A5.9 Alloy Steel Welding Wire

- Mig Welding Wire Nickel Alloy Wire

- Enameled Resistance Wire

- 0.12mm High-Stability Manganin Wire

- Color Enamelled Stainless Steel 316 304 Enameled Nickel Alloy Wire

- Copper Nickel Wires Electric Wire

- CuMn12Ni Microfilament Enamelled Manganin Wire

- Enameled CNickel Chrome Alloy Wire

- Enameled Ni80Cr20 Nichrome 60-23 NiCr6015 Resistance Alloy Wire

- Enameled Ni80Cr20 Nichrome 80-20 NiCr Resistance Alloy Wire

- Enamelled Copper Wire for Transformer Motor

- Enamelled Iron-Chromium Aluminum FeCrAl Alloy Wire

- Enamelled Manganin Wire

- Enamelled Resistance Wire

- Insulated Enameled Solid PEI Copper Nickel Manganese Alloy Manganin 43 47 Wire

- High Temperature Resistance Nichrome Enameled Wire

- Highly Insulated Enameled Wire

- High-temperature-resistant 240C Enameled Wire

- Insulated 0.08mm Manganin Copper Enamel Resistance Frp Glass Awg Wire

- Ni80Cr20 Enamelled NiCrA Wire for Motor Winding

- Ni80Cr20 Enamelled NiCrA Wire

- Nichrome Ni60Cr15-Ni35Cr20 Enameled Wire with High Temperature Resistance

- Nickel Alloy Wire

- NICR Enameled Copper Nickel Chrome Nichrome Alloy Resistance Wire

- Various Colours Enamelled Iron-Chromium Aluminum FeCrAl Alloy Wire

- Manganin 29 Copper Strips

- Resistance Heating Alloy

- Contact Us

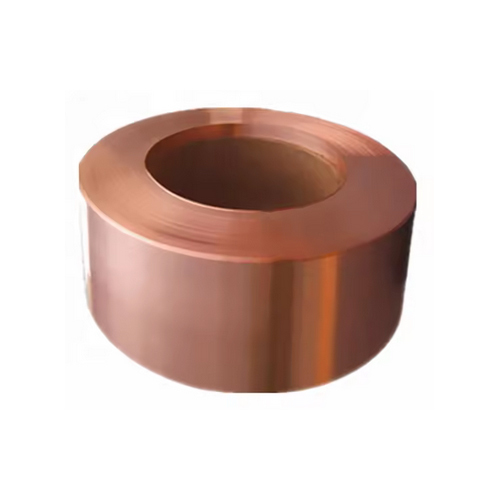

Copper and Manganin Welding Strip

Product Details:

- Purity 99.9% (Copper), 83% Cu / 13% Mn / 4% Ni (Manganin)

- Hardness Soft to Half Hard

- Strength High Electrical and Mechanical Strength

- Product Type Welding Strip

- Material High Purity Copper & Manganin Alloy

- Alloy Copper, Manganin (Copper-Manganese-Nickel)

- Shape Strip

- Click to view more

X

Copper and Manganin Welding Strip Product Specifications

- 0.05%

- Battery Tab Welding, Electrical Welding, Fuse Links, Electronics

- Customizable, typically 0.050.5 mm thickness, widths 2100 mm

- Copper: Reddish-Brown; Manganin: Dull Silver

- Strip

- High Electrical and Mechanical Strength

- Soft to Half Hard

- High Purity Copper & Manganin Alloy

- Welding Strip

- 99.9% (Copper), 83% Cu / 13% Mn / 4% Ni (Manganin)

- Copper (Cu), Manganin (Cu-Mn-Ni alloy)

- Copper, Manganin (Copper-Manganese-Nickel)

- Up to 120C (Continuous), 200C (Intermittent)

- Copper: 16.7 x 10/K; Manganin: 14.5 x 10/K

- ASTM, DIN, JIS Compliant

- Slit Edge / Deburred Edge

- Copper: 200250 MPa; Manganin: 370400 MPa

- Bright, Smooth, Burr Free

- Coil/ Roll/ Customized

- Manganin: 0.430.48 m

- 35%

- Copper: 8.96 g/cm; Manganin: 8.4 g/cm

- Copper: ~99.5% IACS, Manganin: 11-15% IACS

Copper and Manganin Welding Strip Trade Information

- Cash in Advance (CID)

- 5000 Per Month

- 2-10 Days

- All India

Product Description

Experience the acclaimed Copper and Manganin Welding Strip, famed for its immaculate design and exclusive quality. Featuring unmatchable conductivity-Copper at ~99.5% IACS and Manganin at 11-15% IACS-these strips provide high electrical and mechanical strength. Each strip is customizable in dimension and packaging, adhering to rigorous ASTM, DIN, and JIS standards. Grab this high-purity product with a bright, burr-free surface; density up to 8.96 g/cm3; and excellent thermal expansion properties. Perfect for electrical and battery welding applications, these strips are prized by manufacturers, exporters, and suppliers worldwide.

Features & Competitive Advantages of Copper and Manganin Welding Strips

Our Copper and Manganin Welding Strips are primarily used for battery tab welding, fuse links, electronic assemblies, and specialized electrical welding. These strips offer exceptional features like high conductivity, customizable thickness and width, renowned durability, and flawless surface finish. The competitive edge lies in their unmatchable mechanical strength, ASTM, DIN, and JIS compliance, and flexible hardness options, ensuring performance excellence and reliability for demanding industrial applications.

Order Processing, Payment Terms & Delivery for Copper and Manganin Strips

We ensure seamless order processing, partnering with reliable transport services for prompt drop-off at your location. Standard delivery times are quick and efficient globally. Payment terms are flexible to fit client needs. Sample policy enables evaluation before bulk orders. Our dedicated support and competitive logistics guarantee client satisfaction from inquiry to delivery, making us a preferred exporter and supplier for Copper and Manganin Welding Strips in China and worldwide.

Features & Competitive Advantages of Copper and Manganin Welding Strips

Our Copper and Manganin Welding Strips are primarily used for battery tab welding, fuse links, electronic assemblies, and specialized electrical welding. These strips offer exceptional features like high conductivity, customizable thickness and width, renowned durability, and flawless surface finish. The competitive edge lies in their unmatchable mechanical strength, ASTM, DIN, and JIS compliance, and flexible hardness options, ensuring performance excellence and reliability for demanding industrial applications.

Order Processing, Payment Terms & Delivery for Copper and Manganin Strips

We ensure seamless order processing, partnering with reliable transport services for prompt drop-off at your location. Standard delivery times are quick and efficient globally. Payment terms are flexible to fit client needs. Sample policy enables evaluation before bulk orders. Our dedicated support and competitive logistics guarantee client satisfaction from inquiry to delivery, making us a preferred exporter and supplier for Copper and Manganin Welding Strips in China and worldwide.

FAQ's of Copper and Manganin Welding Strip:

Q: How can I customize the dimensions or packaging of Copper and Manganin Welding Strips for my specific application?

A: You may specify your required thickness, width, and packaging type (coil, roll, or custom) during order placement. Our team will tailor the strips according to your project's unique requirements.Q: What industries commonly use Copper and Manganin Welding Strips?

A: These strips are widely utilized in battery pack assembly, electrical welding, fuse manufacturing, and varied electronic applications, owing to their high conductivity and mechanical integrity.Q: When can I expect delivery after placing an order for Copper and Manganin Welding Strips?

A: Once your order is processed, we coordinate with established transport services for swift drop-off. Typical delivery timeframes will be shared based on your location and order size.Q: Where are your Copper and Manganin Welding Strips manufactured and exported from?

A: Our strips are manufactured in China, adhering to global quality standards, and are exported worldwide through a robust supply network.Q: What is the benefit of using strips with a burr-free, bright surface finish?

A: A burr-free and bright surface ensures smooth installation, reduces electrical resistance at contact points, minimizes risk of short circuits, and enhances component longevity.Q: What is your sample policy for Copper and Manganin Welding Strips?

A: We provide samples upon request, allowing clients to evaluate quality before confirming large orders. Please contact us to initiate a sample shipment.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese